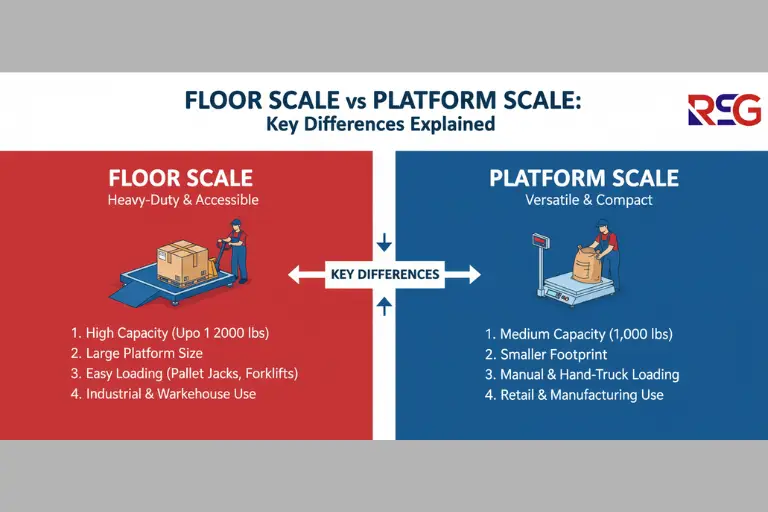

Floor Scale vs Platform Scale: Key Differences Explained

In the realm of industrial and commercial weighing, terms like “floor scale” and “platform scale” are often used interchangeably, leading to confusion among buyers. However, these two types of scales serve distinct purposes, with differences in design, functionality, and application that can impact efficiency and cost. Whether you’re managing a warehouse, manufacturing facility, or retail operation, understanding the nuances between a floor scale and a platform scale is essential for selecting the right equipment. This article breaks down the key differences, helping you make an informed decision tailored to your needs.

Defining Floor Scales and Platform Scales

At their core, both floor scales and platform scales are weighing devices designed for heavy loads, but their structures and uses set them apart. A platform scale typically features a flat, elevated platform where items are placed for measurement. It’s versatile and can be portable or stationary, often used in settings like shipping departments or labs. On the other hand, a floor scale is a low-profile weighing system, often integrated into the floor or pit-mounted, allowing vehicles or large pallets to roll directly onto it. This design minimizes the need for ramps and enhances accessibility for heavy-duty operations.

While platform scales are more general-purpose, floor scales are specialized for high-capacity, industrial environments. Both rely on load cells for accurate readings, but their physical configurations influence installation, maintenance, and performance.

Design and Construction Differences

The most apparent differences lie in their build, which affects usability and integration.

Profile and Installation: Platform scales have a raised platform, usually 2-6 inches high, requiring users to lift or roll items onto it. Floor scales are flush with the ground or slightly recessed, making them ideal for seamless vehicle access without elevation changes.

Size and Portability: Platform scales come in various sizes, from small bench models to large industrial ones, and many are portable with wheels. Floor scales are typically larger and fixed in place, often custom-installed in concrete pits for stability.

Materials and Durability: Both use robust materials like steel, but floor scales are built for extreme wear, with reinforced frames to handle constant heavy traffic. Platform scales may include ramps or handles for easier movement.

These design elements make floor scales more permanent fixtures, while platform scales offer flexibility.

Capacity and Accuracy Variations

Capacity is a critical factor, as it determines the scale’s suitability for different loads.

Weight Capacity: Floor scales often handle extremely heavy loads, ranging from 5,000 to 100,000 pounds or more, suitable for trucks or industrial machinery. Platform scales typically cap at 10,000-20,000 pounds, though some models go higher, making them better for pallets or smaller vehicles.

Accuracy and Precision: Both provide high accuracy, often within 0.1% of the load, but floor scales excel in dynamic weighing (e.g., weighing moving vehicles) due to their stable, low-profile design. Platform scales are precise for static loads but may require calibration for uneven surfaces.

Resolution: Platform scales might offer finer resolutions for lighter items, while floor scales prioritize robustness over minute measurements.

For businesses dealing with massive weights, floor scales provide the edge in capacity and reliability.

Applications and Use Cases

The choice between a floor scale and a platform scale often hinges on the specific application.

Floor Scale Applications: Ideal for warehouses, shipping yards, and manufacturing plants where vehicles like forklifts or trucks need weighing. They’re used for inbound/outbound freight, inventory control, and even livestock weighing in agricultural settings. Their pit-mounted design allows for easy, continuous use without disrupting workflows.

Platform Scale Applications: Versatile for retail, food processing, and small-scale manufacturing. For example, a bakery might use a platform scale for ingredient batches, or a shipping company for parcel verification. Portable models are great for on-site jobs or temporary setups.

Environmental Suitability: Floor scales thrive in harsh, industrial environments with dust or moisture, while platform scales are adaptable but may need protective covers for outdoor use.

In summary, floor scales are for heavy, vehicle-based weighing, whereas platform scales suit a broader range of lighter, more varied tasks.

Advantages and Disadvantages

Each type has its strengths and drawbacks, influencing cost and practicality.

Floor Scale Advantages:

- Seamless integration for high-traffic areas.

- Superior capacity for extreme loads.

- Reduced risk of damage from heavy impacts.

Floor Scale Disadvantages:

- Higher installation costs and complexity.

- Less portable, limiting flexibility.

- Requires professional setup and maintenance.

Platform Scale Advantages:

- Easier to install and relocate.

- Cost-effective for moderate loads.

- Versatile for multiple applications.

Platform Scale Disadvantages:

- May need ramps for heavy items.

- Less durable in high-traffic, rough environments.

- Potential for accuracy issues on uneven floors.

Weighing these pros and cons helps align the scale with your operational needs.

Cost Considerations and Maintenance

Budget plays a significant role in decision-making.

Initial Costs: Floor scales are more expensive upfront due to installation (often

50,000), while platform scales range from

10,000, depending on size.

Maintenance: Floor scales need periodic pit inspections and calibration, which can be costly. Platform scales are simpler to maintain, with replaceable parts like load cells.

Long-Term Value: Floor scales offer durability for heavy use, potentially lowering replacement costs, whereas platform scales provide better ROI for varied, less intensive applications.

Factor in your budget and usage frequency to determine the best fit.

Choosing the Right Scale for Your Business

To select between a floor scale and a platform scale, assess your requirements.

Evaluate Load Types: If weighing vehicles or large pallets daily, opt for a floor scale. For general-purpose or portable needs, choose a platform scale.

Space and Installation: Consider floor space; floor scales need dedicated areas, while platform scales fit into existing setups.

Future Needs: Think scalability platform scales allow for expansion, while floor scales are fixed investments.

Consult Experts: Work with suppliers for custom solutions, ensuring compliance with standards like NTEP for legal-for-trade use.

Testing samples or demos can provide hands-on insights.

Technological Integrations and Future Trends

Modern scales incorporate tech for enhanced functionality.

Digital Features: Both can include LCD displays, data logging, and connectivity to software for inventory tracking. Platform scales often have more app integrations for mobile use.

Innovations: Expect advancements like wireless load cells and AI for predictive maintenance, benefiting both types.

Sustainability: Eco-friendly materials are emerging, reducing environmental impact.

Staying updated ensures you choose a forward-compatible scale.

While floor scales and platform scales share similarities, their differences in design, capacity, and application make them suited for distinct roles. Floor scales excel in heavy-duty, industrial settings with their robust, integrated build, whereas platform scales offer versatility and ease for broader uses. By understanding these key distinctions, businesses can invest wisely, boosting efficiency and productivity. Whether you’re upgrading your warehouse or starting anew, the right scale can transform your operations choose based on your specific needs for optimal results.