How to Choose the Right Floor Scale for Your Needs

Accurate weight measurement is essential for cost control, compliance, and operational efficiency in a variety of businesses. Floor scales are essential tools for businesses that require precise weight measurements for inventory management, shipping, and production processes. However, choosing the best floor scale for your unique requirements might be difficult given the large variety of models on the market. This article will guide you through the key factors to consider when choosing the right floor scale for your business.

Determine Your Weight Capacity Requirements

The first step in selecting a floor scale is to determine the weight capacity you need. Floor scales come in various weight capacities, typically ranging from a few hundred pounds to several tons. Consider the maximum weight of the items you will be weighing, including any potential future needs. Selecting a scale that can manage your largest loads without sacrificing precision or security is crucial.

Additionally, consider the frequency of use. If you plan to weigh heavy items regularly, investing in a scale with a higher weight capacity may be more cost-effective in the long run. On the other hand, if your needs are more modest, a lower-capacity scale may suffice.

Consider the Size and Dimensions

The size and dimensions of the floor scale are critical factors to consider, as they must fit within your workspace and accommodate the items you intend to weigh. Measure the available space in your facility to ensure that the scale will fit comfortably without obstructing workflow.

Additionally, consider the platform size of the scale. A larger platform may be necessary for weighing bulky items or pallets, while a smaller platform may be suitable for smaller packages or individual items. Ensure that the scale’s dimensions align with your operational needs to facilitate efficient weighing processes.

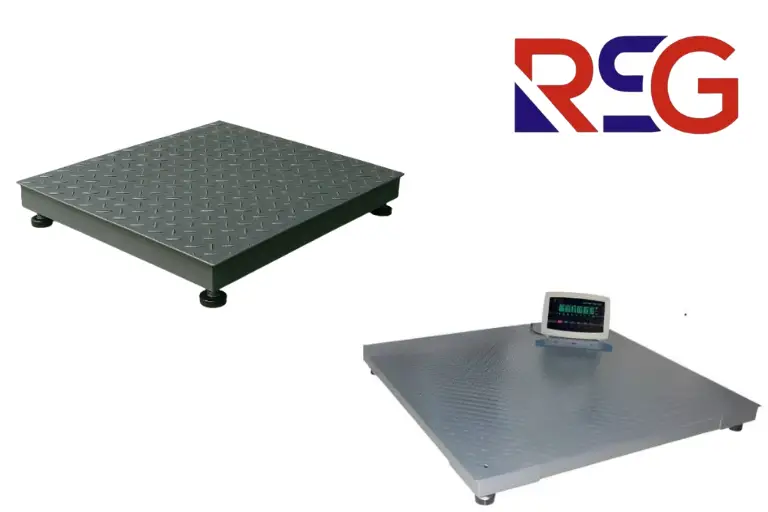

Choose the Right Type of Floor Scale

Floor scales come in a variety of forms, each intended for a particular use. Understanding the different types can help you make an informed decision:

- Mechanical Floor Scales: These scales measure weight using a system of springs and levers. They are typically more affordable but may require more maintenance and calibration compared to digital scales.

- Digital Floor Scales: Digital scales provide electronic weight readings, often with additional features such as data storage, connectivity, and advanced display options. They are generally more user-friendly and offer greater accuracy.

- Portable Floor Scales: If you need to weigh items in different locations, consider a portable floor scale. These scales frequently have built-in wheels or handles and are made to be portable.

- Heavy-Duty Floor Scales: Heavy-duty floor scales are designed to endure challenging conditions and large loads in industrial settings. They are typically constructed from robust materials and designed for durability.

Selecting the right type of floor scale depends on your specific application, environment, and budget.

Evaluate Accuracy and Precision

Accuracy is paramount when it comes to weighing items, as even minor discrepancies can lead to significant financial losses or compliance issues. When choosing a floor scale, look for models that offer high accuracy and precision. Check the scale’s specifications for its accuracy rating, typically expressed as a percentage of the full scale capacity.

Additionally, consider the scale’s resolution, which refers to the smallest increment it can measure. A higher resolution allows for more precise measurements, which can be particularly important in industries where weight is closely monitored, such as food processing or pharmaceuticals.

Look for Additional Features

Numerous features that might improve their use and functionality are frequently included with contemporary floor scales. When evaluating potential scales, consider the following features:

- Data Connectivity: Many digital floor scales offer connectivity options, such as USB, Bluetooth, or Wi-Fi, allowing you to transfer weight data to computers or inventory management systems. This feature can streamline your operations and improve data accuracy.

- Display Options: Look for scales with clear, easy-to-read displays. Some models offer backlit screens or remote displays, which can be beneficial in low-light environments or when the scale is positioned at a distance.

- Tare Function: A tare function allows you to subtract the weight of containers or packaging, providing a net weight measurement. This feature is particularly useful in applications where items are weighed in boxes or pallets.

- Calibration Options: Ensure that the scale you choose has easy calibration options. Regular calibration is essential for maintaining accuracy, and a scale that allows for simple adjustments can save time and effort.

Assess Durability and Build Quality

The durability and build quality of a floor scale are crucial, especially in industrial environments where they may be exposed to heavy loads, moisture, or harsh conditions. Look for scales constructed from high-quality materials, such as stainless steel or heavy-duty aluminum, which can withstand wear and tear.

Additionally, consider the scale’s IP rating, which indicates its resistance to dust and water. A higher IP rating is essential for scales used in environments where exposure to moisture or contaminants is a concern.

Review Compliance and Certification

Depending on your industry, you may need to comply with specific regulations regarding weight measurement. Ensure that the floor scale you choose meets any relevant industry standards and certifications, such as NTEP (National Type Evaluation Program) or OIML (International Organization of Legal Metrology). These certifications indicate that the scale has been tested and approved for accuracy and reliability.

Consider Budget and Total Cost of Ownership

While price is an important factor, it should not be the sole consideration when choosing a floor scale. Evaluate the total cost of ownership, which includes not only the initial purchase price but also factors such as maintenance, calibration, and potential replacement costs.

Investing in a high-quality floor scale may involve a higher upfront cost, but it can lead to significant savings in the long run due to reduced maintenance and increased operational efficiency. Consider your budget and weigh it against the potential benefits of a more reliable and accurate scale.

Choosing the right floor scale for your needs is a critical decision that can significantly impact your operations. By considering factors such as weight capacity, size, type, accuracy, additional features, durability, compliance, and budget, you can make an informed choice that aligns with your specific requirements.

Investing time in selecting the right floor scale will pay off in the long run, ensuring that you have a reliable tool for accurate weight measurement. Whether you are in manufacturing, logistics, or any other industry that relies on precise weighing, the right floor scale can enhance your efficiency, improve compliance, and contribute to your overall success.