What Is a Platform Scale and How Does It Work?

Platform weighing scales are a vital tool used across a wide range of industries to measure the weight of goods with precision and efficiency. Whether in manufacturing, logistics, agriculture, retail, or food processing, these scales provide the foundation for accurate weight measurement essential for quality control, inventory management, and regulatory compliance. But what exactly is a platform weighing scale, and how does it function? This article provides a comprehensive overview of platform weighing scales, their components, and their applications.

What Is a Platform Scale?

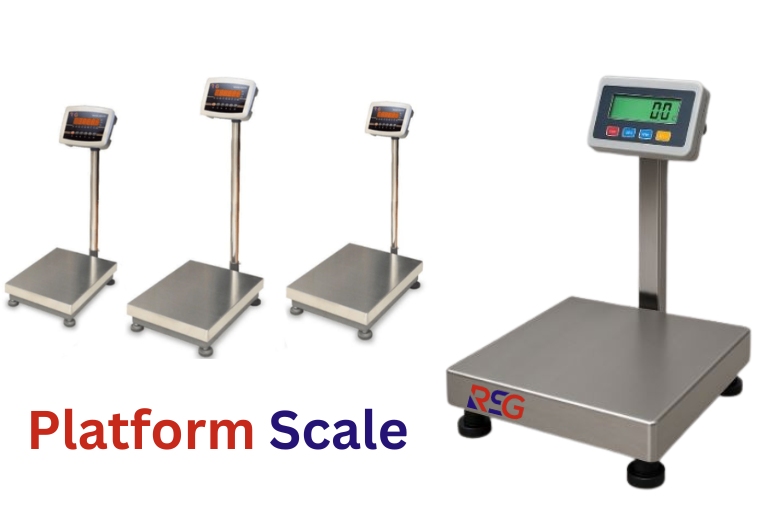

A platform scale is a type of industrial or commercial scale that features a flat platform surface designed to support items for weighing. These scales come in various sizes and capacities, from compact table top models for smaller loads to large floor-mounted systems for weighing heavy equipment, pallets, or vehicles.

They are known for their robust construction, ease of use, and high level of accuracy. Platform weighing scales can be mechanical or digital, though modern applications mostly rely on digital versions due to their precision, ease of calibration, and data integration capabilities.

Components of a Platform Weighing Scale

To understand how a platform scale works, it is essential to break down its key components:

Platform Surface: The flat surface where items are placed for weighing. It is typically made of stainless steel or mild steel with anti-corrosive coatings to ensure durability.

Load Cells: These are the heart of the weighing mechanism. Load cells are sensors that convert the weight or force applied on the platform into an electrical signal. Most platform scales use strain gauge load cells.

Indicator/Display Unit: This is the control panel that shows the measured weight. It can also provide additional information like tare weight, gross weight, or cumulative weight, depending on the model.

Frame/Base: The structural component that houses the load cells and supports the platform. It ensures stability and accuracy during weighing.

Power Source: Most digital platform scales operate on electricity or rechargeable batteries.

Connectivity Ports: In advanced systems, these ports allow integration with printers, computers, or software systems for data management and reporting.

How Does a Platform Weighing Scale Work?

The functioning of a platform weighing scale revolves around the interaction between the weight applied and the load cells underneath the platform. Here’s a step-by-step breakdown of the process:

Placing the Load: An object is placed on the scale’s platform. The object exerts force (weight) on the platform.

Load Cell Activation: The load cells beneath the platform sense the applied force. Each load cell slightly deforms under the weight, generating a corresponding electrical signal.

Signal Conversion: The analogue signal from the load cells is converted into a digital signal via an analogue-to-digital converter.

Data Processing: The digital signal is processed by the scale’s microprocessor to calculate the weight.

Display of Results: The calculated weight is shown on the indicator or digital display screen, usually in kilograms, pounds, or other configurable units.

Data Output (Optional): In connected systems, the weight data can be transmitted to external devices for record-keeping or further analys

Applications of Platform Weighing Scales

Platform weighing scales are used in a wide array of industries due to their versatility and reliability. Here are some common applications:

Manufacturing: For measuring raw materials, components and finished goods.

Logistics and Warehousing: To weigh packages, pallets, and cargo before shipping or storage.

Agriculture: Used for weighing crops, livestock feed, and farm produce.

Retail: Employed in grocery stores or markets for weighing items sold by weight.

Food Processing: Ensures portion control, consistency, and compliance with hygiene standards.

Recycling and Waste Management: Measures the weight of recyclable materials and waste loads

Benefits of Using Platform Weighing Scales

High Accuracy: Provides precise weight measurements, reducing errors and ensuring quality control.

Durability: Built to withstand heavy loads and harsh environments.

Ease of Use: Simple to operate with minimal training required.

Customizability: Available in a wide range of sizes, capacities, and features to suit different applications.

Data Integration: Can be integrated with business systems for streamlined operations.

Maintenance and Calibration

To ensure consistent performance, platform scales should be regularly maintained and calibrated. Dust and debris should be cleaned from the platform and load cells. Scheduled calibration ensures the accuracy of measurements, especially in industries with strict regulatory standards.

Platform weighing scales are indispensable tools in modern industry, offering a blend of accuracy, versatility, and efficiency. Understanding how these scales work helps users select the right model for their specific needs and ensures optimal performance in day-to-day operations. Whether in a warehouse, farm, factory, or retail outlet, a well-maintained platform weighing scale can be a crucial component of operational success.